ABOUT THE PROJECT

Our Vision :

COROB aims to develop a flexible, cooperative and intelligent multi-robotic solution for arc welding-based manufacturing processes (joining and additive manufacturing), to offer new operational capabilities that allow to increase the efficiency and improve the flexibility of industrial processes.

COROB, conceived as a global solution, will employ a cooperative multi-robot system powered by Inspection, Monitoring, Control and AI techniques to optimize the welding process, and the adjacent manufacturing stages for time, cost, energy, and resource reduction.

The data generated will be processed in a data acquisition platform to feed the AI technologies, addressing optimisation, search, planning, and analysis, ensuring AI robustness and trustworthiness.

Use Cases :

USE CASE 1

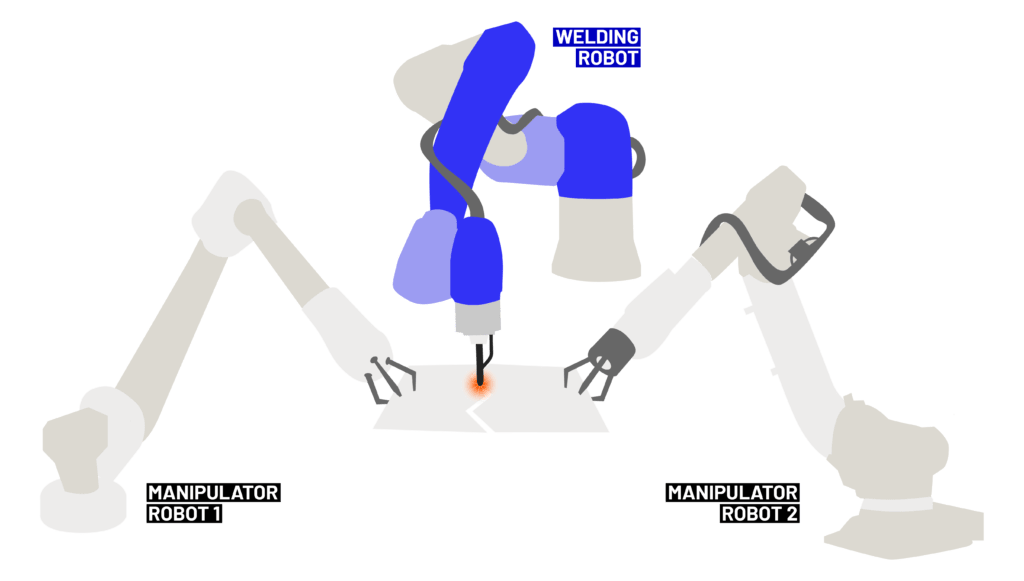

Multi-robot cooperative welding

This use-case will focus on a cooperative multi-robot system for flexible manufacturing. The welding process will be performed using jigless robotic approach, defined as robotic welding without tools/jigs in which two manipulator robots hold and present the workpieces to one welding robots.

USE CASE 2

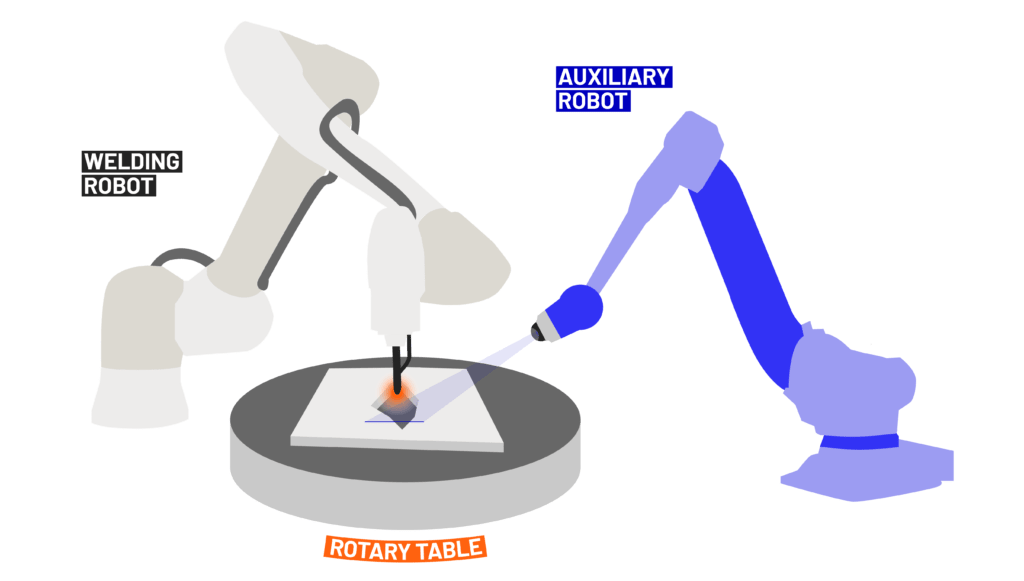

Multi-robot cell for tooling repair using WAAM

This use case will deploy a multi-robot cooperative robotic cell for repair of tooling. The main robot will be the processing robot, equipped with a WAAM arc-welding head as an end effector, taking care of the repair tasks. Together with a 2-DoF rotary table, it will constitute an 8-DoF processing system, capable of repairing very complex geometries.

Additionally, a smaller, auxiliary robot will be integrated in the cell and will be responsible for the auxiliary processing tasks. A core technology integrated in the robot will be 3D scanning, while other technologies (e.g. inspection, part treatment, finishing, etc.) will be examined through the Open call of the project.